PHONE: 607.772.1794

FAX: 607.772.1797

EMAIL: SALES@EMSTECH.COM

265 THRUWAY PARK DR, WEST HENRIETTA, NY 14586

CAPABILITIES

SMALL ENOUGH TO GET IT DONE FAST. BIG ENOUGH TO GET IT DONE RIGHT.

-

THRU-HOLE ASSEMBLY

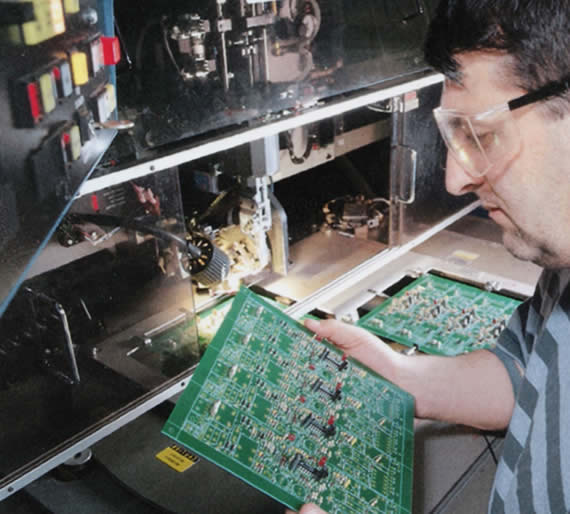

Automated Thru-hole Assembly

Automated assembly is used to assemble axial, radial, and DIP components accurately, quickly, and cost effectively. EMS's operators use SPC to monitor and maintain the process, ensuring quality levels unattainable by manual assembly. Board sizes up to 18" x 24".

Progressive Manual Assembly

- Automated line with programmable dwell time

- Visual aids document each stations requirements

- Reducing human error in manual operations by reducing the process variables

Intricate Manual Assembly

EMS Manual Assembly Technicians have an average of over 10 years of experience installing complex Custom Magnetics, cabling, and other non standard components.

-

In-Circuit / Functional Test Development

EMS will work with you to develop a test strategy to meet your end point requirements. EMS Test Engineering will design and build the hardware and software to ensure your Customers receive only functional, quality product.

-

Design Review / Recommendations

Design For Manufacturability can decrease assembly cost and assembly lead time. Further benefits can be realized in the form of increased first pass yields and field reliability.

EMS can provide advice sown from over 40 years of "hands on" experience assembling and testing electronic assemblies.

-

Conformal Coating

High humidity and other aggressive environments can have negative effects on uncoated circuit assemblies over time. High humidity can lower (SIR) Surface Insulation Resistance (leakage, cross talk) and dust, dirt, and other pollutants can trap moisture on the P.W.B. surface and magnify these effects. Moisture also provides the necessary medium for metallic growth and corrosion.

Our standard Acrylic Conformal Coating is Humiseal 1B73. It meets MIL-I-46058C and IPC-CC-830 specifications. It is ROHS 2002/95/EC Compliant and is recognized under UL file number E105698.

We also use Humiseal 1B31, also an acrylic.

Our standard silicone coating is Humiseal 1C49LV and is recognized by Underwriters Laboratories file number E1056978. It meets MIL-I-46058C and IPC-CC-830 and is ROHS 2002/95/EC compliant.

Detailed specifications can be found at humiseal.com. Other manufacturers/formulas can be quoted upon request.

-

Proto-type Assembly

When it comes to Proto-type assembly we know that turnaround time is critical, and changing documentation and materials are the rule, rather than the exception. EMS has developed separate procedures to most effectively handle this sensitive stage in your products' life cycle.

Our Proto-Type team has been selected from our most experienced manufacturing technicians, based on their ability to identify, define and solve problems.

-

Surface Mount Assembly

Placement Equipment by MyData

- Passives as Small as 0402's

- BGA with 1100+ Ball Count

- Board Sizes up to 21" x 24"

- "On the Fly" Component Value Verification

- Vision assisted Fine Pitch Placement to 12 mil Spacing

- Automated Optical Inspection by Mirtec

-

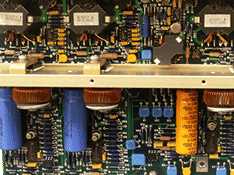

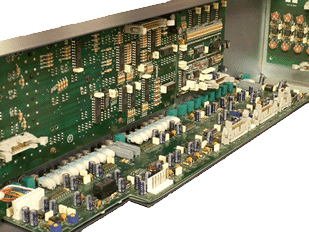

Panel and Chassis Assembly

Whatever your requirements, from circuit assembly only to full box build, custommetal fabrication, powder coating, silk-screening, injection molding and extrusion - EMS has the sourcing and experience to deliver a quality product on-time.

-

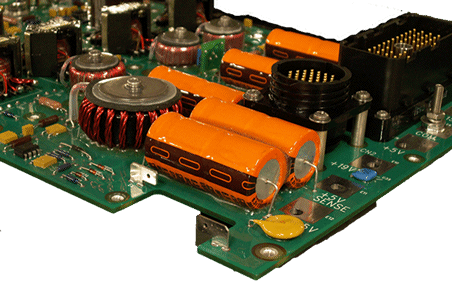

High Voltage Ball Soldering

High Voltage Ball Soldering is a technique specified for certain High Voltage applications to reduce a circuit's susceptibility to current arcing. The technique is more of an art than a science, and our manual soldering specialists have years of experience with this difficult technique.

Assemblies requiring this solder joint geometry frequently have special component mounting requirements such as separation air gaps, standoff heights, or special lead forming requirements.

-

Document Control

Accurate, thorough and unambiguous documentation is the only starting point that leads to a successful OEM/Contractor relationship.

At EMS your Product Documentation is "Carved in Stone". We will make no changes or substitutions without your written approval.

-

Material Procurement

We will review our material costs together with you line by line, to take advantage of every possible cost savings.

"VANTAGE" ENTERPRISE RESOURCE PLANNING (ERP) SYSTEM

- Provides Complete Material Resource Planning Capability

- Instant Access to Forecasted Component Requirements

- Component Usage History:

- Vendor(s)

- Price

- Quantity

- Lead Time

- Date(s)

- JIT Materials Scheduling

EMS maintains a relationship with over 30 Electronic Component Distributors and Brokers. We consider these Supplier partnerships to be a vital asset in our pursuit to meet the needs of our Customers.

MADE IN USA

MADE IN USA